Wind Turbine Power Brushes

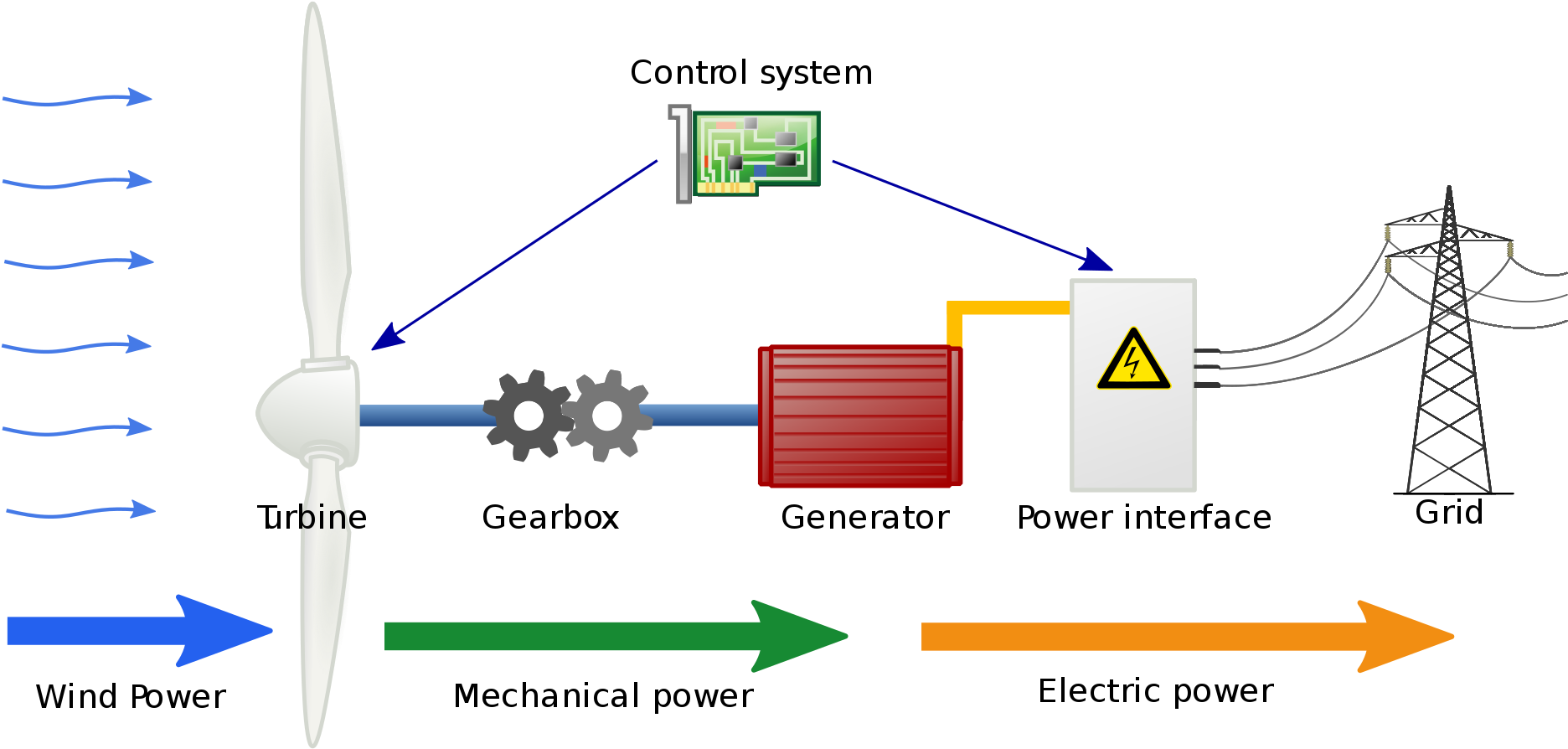

Wind Turbines operate on the basic principle that the kinetic energy of wind creates lift and turns its propeller-like blades. The blades of the turbine are connected to a drive shaft that spins a generator and in turn generates electricity. As technology continues to move forward the cost to develop and manufacture wind turbine parts becomes increasingly affordable and the efficiency of wind turbine systems increases.

The primary types of wind turbines are vertical axis and horizontal axis wind turbines. By far the most common type is the horizontal axis wind turbine; these turbines are constructed in such a way that all of the components are positioned on top of a tall tower with the blades facing the wind. On the other hand, the vertical axis turbine is constructed with all of the main components close to the ground. Like the horizontal axis turbines vertical axis turbines are often designed to be lift-based. While this design is easier to maintain and transport it’s also less efficient and has a low starting torque.

Wind turbine power brushes are an important component of wind turbines that are essential to their proper function. Brushes are electrical conductors that work with slip rings and brush holders to protect vital wind turbine components from static electricity and other viral currents. While power brushes need moderate wear for proper wind-turbine operation and maintenance, excessive wear can result in reduced internal isolation which forces early component replacement. Carbex Carbon Power Brushes are unique in that they can withstand a great deal of wear and tear while maintaining high quality functionality. These power brushes also good mechanical stability, low friction coefficient, and high electrical conductivity.

Although copper brushes are widely used in the wind power industry, they tend to have a shorter lifespan and require greater

maintenance due to higher carbon dust production.

Carbex Carbon’s Silver Graphite Power Brushes outperform copper brushes

in both longevity, lifetime performance, and extreme climates. It can be observed that silver brushes wear in a more distributed

fashion, offer a reduced oxidation level, and tend to stay cleaner. When compared to their copper counterparts’ studies show

that on average brush life can be up to 30% longer in silver brushes.

Contact our tech team with any questions or for a custom quote.