Carbon-Carbon (CFC) for Heat Treatment

Carbon-Carbon Composite (CFC) is the choice material for the heat-treat industry. It is designed to exceed temperature capabilities of super-alloys and can withstand temperatures of well over 2000ºC (3600F) without losing strength and rigidity. C/C composite material has low thermal mass, high strength-to-weight ratio at temperature and negligible thermal deformation, creating favorable net/tare load weight ratios when used for fixtures and grids. This allows for rapid heating and cooling rates, heavy part loading and improvements in part distortion. C/C also has excellent fatigue resistance, which minimizes issues with crack propagation.

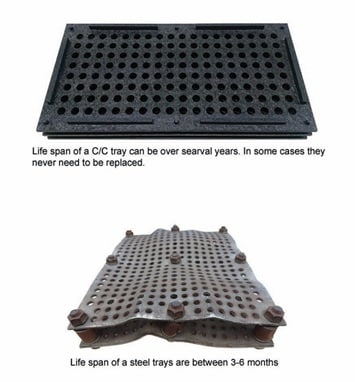

As a lightweight solution C/C racks and fixtures are 50-70% lighter in weight than conventional materials. By allowing for a more compact fixture design, more material can be loaded into the furnace with each run resulting in a large increase for productivity. All of this allows for a better cost performance overall when using Carbon-carbon compared with steel alloys or other materials.

At Graphitestore, our technical team can discuss the parameters of your furnace and the parts being treated to help customize C/C fixture solutions to your needs and performance requirements. Carbon-carbon racks can be machined to spec. Check out our catalog parts or submit a request for quote for custom parts.